- Joined

- Apr 1, 2011

- Messages

- 15,187

- Helped

- 2,900

- Reputation

- 5,812

- Reaction score

- 2,982

- Trophy points

- 1,393

- Location

- Minneapolis, Minnesota, USA

- Activity points

- 113,782

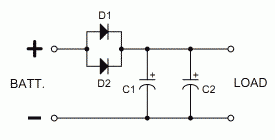

The first schematic will not allow the capacitors to power the load.

By the way, in frigid cold it's conceivable that parts can shift inside a capacitor, either the wires or the paper/wax/chemicals, etc.

This can cause reduced ability to hold a charge, or at worst a short circuited capacitor.

Did you test that the caps can hold a charge in cold temp? Each cap independently?

And that they can provide 12 V to a load of maybe 1000 ohms? (Or based on whatever is your instrument's current draw.)

For several seconds?

By the way, in frigid cold it's conceivable that parts can shift inside a capacitor, either the wires or the paper/wax/chemicals, etc.

This can cause reduced ability to hold a charge, or at worst a short circuited capacitor.

Did you test that the caps can hold a charge in cold temp? Each cap independently?

And that they can provide 12 V to a load of maybe 1000 ohms? (Or based on whatever is your instrument's current draw.)

For several seconds?