kabaleevisu

Advanced Member level 2

- Joined

- Apr 14, 2010

- Messages

- 616

- Helped

- 85

- Reputation

- 170

- Reaction score

- 81

- Trophy points

- 1,308

- Location

- Chennai,India

- Activity points

- 4,512

where will core and prepreg can be used in this stack-up ?

Hi everyone,

in my design has BGA(256pins),DC-DC converter,opto isolator,schmitt trigger,connector is avaiable and power and ground are

1.5V(1.5A),3.3V(2A),5V(1A),+15V_FTR,+15V_DC,5VDC,+ 5V_FTR,+24V_ISO,ISO_GND,GND,AGND,minimum pitch details for package

tssop package-0.65mm,soic-1.27mm,BGA Pitch-1mm

i am planning to design in 6 layer ,Here i like to choose any one

---------------- mounding pads/low freq signal

---------------- Ground

---------------- Ground

---------------- Hig freq signal

---------------- High freq signal

---------------- power

---------------- Low freq signal

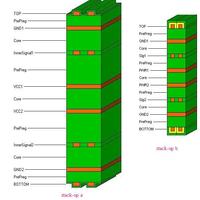

stack -up (a)

---------------- sig(Hi)

---------------- Gnd

---------------- sig(v1)

---------------- sig(H2)

---------------- PWR

---------------- SIg(v2)

stack -up (b)

----------------GND/Mounding PADS

----------------SIG

----------------GND

----------------PWR

----------------SIG

----------------GND

stack -up (c)

i have some queries in my stack-up design

1) where core and preperg will come ?

2) which stack-up is best amoung three ?? why ?? what is horiantal and vertical routing?? what is the use of it ??

3) which dielectrical meterial is used commenly ??

Hi everyone,

in my design has BGA(256pins),DC-DC converter,opto isolator,schmitt trigger,connector is avaiable and power and ground are

1.5V(1.5A),3.3V(2A),5V(1A),+15V_FTR,+15V_DC,5VDC,+ 5V_FTR,+24V_ISO,ISO_GND,GND,AGND,minimum pitch details for package

tssop package-0.65mm,soic-1.27mm,BGA Pitch-1mm

i am planning to design in 6 layer ,Here i like to choose any one

---------------- mounding pads/low freq signal

---------------- Ground

---------------- Ground

---------------- Hig freq signal

---------------- High freq signal

---------------- power

---------------- Low freq signal

stack -up (a)

---------------- sig(Hi)

---------------- Gnd

---------------- sig(v1)

---------------- sig(H2)

---------------- PWR

---------------- SIg(v2)

stack -up (b)

----------------GND/Mounding PADS

----------------SIG

----------------GND

----------------PWR

----------------SIG

----------------GND

stack -up (c)

i have some queries in my stack-up design

1) where core and preperg will come ?

2) which stack-up is best amoung three ?? why ?? what is horiantal and vertical routing?? what is the use of it ??

3) which dielectrical meterial is used commenly ??

Last edited: