Borber

Advanced Member level 5

- Joined

- Dec 31, 1999

- Messages

- 1,600

- Helped

- 235

- Reputation

- 472

- Reaction score

- 111

- Trophy points

- 1,343

- Location

- on third flor

- Activity points

- 11,863

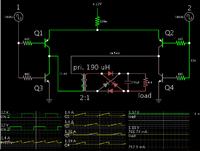

The article says 20/25 turns for transformer. You made it with 150/180 turns windings.