DeepOne

Advanced Member level 2

- Joined

- Feb 26, 2011

- Messages

- 632

- Helped

- 99

- Reputation

- 200

- Reaction score

- 100

- Trophy points

- 28

- Location

- 45N39E, Russia

- Activity points

- 0

Follow along with the video below to see how to install our site as a web app on your home screen.

Note: This feature may not be available in some browsers.

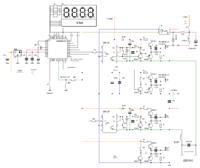

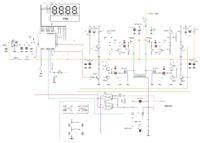

There whole nine pulses on half-wave, so waveform not very close to sine, but this is acceptable for motor application.wave form during load still sine or close to sine?

but, there it is,No Sine table

0 is not shown in table but 9th is already equal to zero.flash unsigned char s_table [9]={7,14,20,23,24,23,20,14,7};

I do not see such projects, but can be something in someplace with automatic waveform corrections.is there any project whose waveform is puresine wave during motor load ?

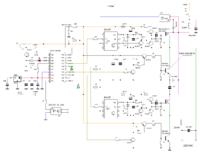

i think not more than 500W with 12V feedingwould the expected output power be when using a single IRF3205 in each side of the H-bridge?

Hi, Sghr220.

When output current exceed some value, voltage on current sense resistor go to sufficient value for opening optocoupler and mcu pin to be shorten to common wire. As result mcu switch off power fets (or that is there provided in microprogram).

Optional resistor on mcu side used for increasing hindrance stability, because internal mcu pull-up has too big resistance.

i think not more than 500W with 12V feeding

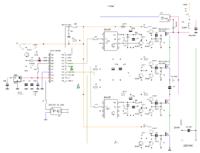

It may be changed in source code or with ADC resistors divider.adjust the trigger voltage for ADc of the micro

In this case It is necessary to take care of voltage limiting for fets G-S. And adjust voltage for mcu battery voltage detector. Also will be necessary worried about mcu source resistor and, of course about transformer.use of this circuit for 24v operation