antenna_abc

Member level 3

edge-launch sma

Hi, everyone. I have a practical question about mounting a SMA connector on a multilayer PCB.

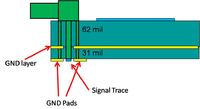

The PCB has two substrate and 3 copper layer, with top and bottom as signal layer, and intermediate as GND layer. And I want to mount the SMA connector on the PCB, with the signal pin connected to the bottom signal layer, as shown in the attachment.

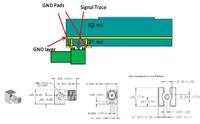

The problem is that the PCB itself is too thick for the edge-launch SMA connector in attachment (a). And since the GND layer is sandwiched by two substrates, it is also very difficult to insert the PCB to the SMA connector slots.

So I am going to use the thru-hole SMA in attachment (b). My question is how to ensure the signal pin and the GND pins are electrically connected to the PCB? Does anyone have the idea about how to make the PCB layout and via holes for this thru-hole SMA connector for multi-layer PCB?

Thanks.

Hi, everyone. I have a practical question about mounting a SMA connector on a multilayer PCB.

The PCB has two substrate and 3 copper layer, with top and bottom as signal layer, and intermediate as GND layer. And I want to mount the SMA connector on the PCB, with the signal pin connected to the bottom signal layer, as shown in the attachment.

The problem is that the PCB itself is too thick for the edge-launch SMA connector in attachment (a). And since the GND layer is sandwiched by two substrates, it is also very difficult to insert the PCB to the SMA connector slots.

So I am going to use the thru-hole SMA in attachment (b). My question is how to ensure the signal pin and the GND pins are electrically connected to the PCB? Does anyone have the idea about how to make the PCB layout and via holes for this thru-hole SMA connector for multi-layer PCB?

Thanks.