abhi@eda

Member level 1

- Joined

- Mar 12, 2013

- Messages

- 41

- Helped

- 0

- Reputation

- 0

- Reaction score

- 0

- Trophy points

- 1,286

- Location

- Bangalore

- Activity points

- 1,679

i am little confused about Torque which is measured in Newton meter...

Aussume,i have a engine which produces a 11Nm of torque at 2500RPM

the shaft of the engine is connected to a steel pipe which weighs 1kg..

so as far as i know,11Nm of torqe is the capacity of engine to turn something which weighs 11Newton and is connected to the center of the shaft at 1 meter distance...

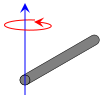

so 11Nm is around 1.1kg-f ,so in the below image i have drawn the illustration,which shows a steel pipe of 1 meter long connected to the shaft,and weighs 1kg...

so the engine which produces over 1.1kg-f of force,can it turn the shaft when it is at rest? or will the engine stall and wont fire up??

Aussume,i have a engine which produces a 11Nm of torque at 2500RPM

the shaft of the engine is connected to a steel pipe which weighs 1kg..

so as far as i know,11Nm of torqe is the capacity of engine to turn something which weighs 11Newton and is connected to the center of the shaft at 1 meter distance...

so 11Nm is around 1.1kg-f ,so in the below image i have drawn the illustration,which shows a steel pipe of 1 meter long connected to the shaft,and weighs 1kg...

so the engine which produces over 1.1kg-f of force,can it turn the shaft when it is at rest? or will the engine stall and wont fire up??