Tractor Beam

Newbie level 4

- Joined

- Dec 8, 2011

- Messages

- 6

- Helped

- 0

- Reputation

- 0

- Reaction score

- 0

- Trophy points

- 1,281

- Activity points

- 1,368

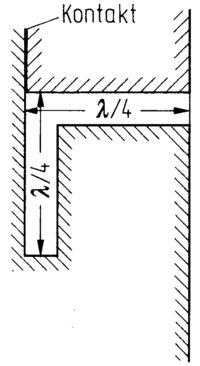

On the microwave oven door itself, on the inside of the door around the perimeter there are a number of cavities. You must pop off a removable plastic cover inside the door to see them.

The cavities are formed from a bunch of bent tabs 3/4 inch wide, 3/4 inch deep, and are spaced every 3/8 inch apart. My oven door has about 40 of these bent tabs.

I assume these have something to do with keeping the microwaves from leaking out through the cracks around the door. With my brief experience with microwave guides I found that it was very difficult to keep them in my home made guides. All the seals between two wave guides would have to be machined very flat and the bolts would have to be well tightened. Even very small gaps would leak a large amount of power. The edge seal around the door on a microwave is no where near this quality of seal yet it still works very well.

What I would like to know is: how do these cavities prevent the microwaves from leaking out. What makes them work?

The cavities are formed from a bunch of bent tabs 3/4 inch wide, 3/4 inch deep, and are spaced every 3/8 inch apart. My oven door has about 40 of these bent tabs.

I assume these have something to do with keeping the microwaves from leaking out through the cracks around the door. With my brief experience with microwave guides I found that it was very difficult to keep them in my home made guides. All the seals between two wave guides would have to be machined very flat and the bolts would have to be well tightened. Even very small gaps would leak a large amount of power. The edge seal around the door on a microwave is no where near this quality of seal yet it still works very well.

What I would like to know is: how do these cavities prevent the microwaves from leaking out. What makes them work?