Qaisar Azeemi

Full Member level 5

- Joined

- Feb 11, 2011

- Messages

- 315

- Helped

- 16

- Reputation

- 32

- Reaction score

- 15

- Trophy points

- 1,298

- Location

- Peshawar, Pakistan, Pakistan

- Activity points

- 3,829

Hi friends!

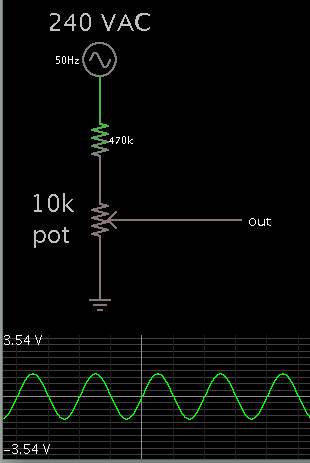

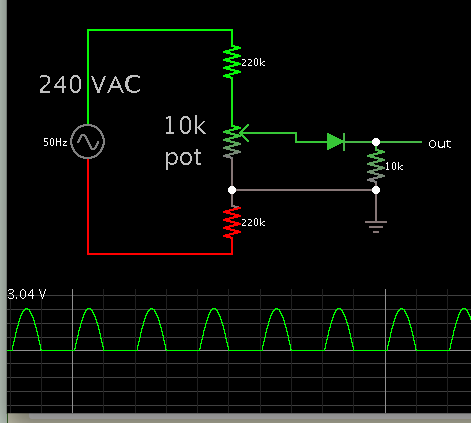

I want to measure the AC line voltages 220V using pin RA5 of Pic16F877A, and display it on LCD Screen. kindly help me with circuit diagram and code. i also studied the mikrochip application note AN521 bu't cant get any specifice solution. they just add a 5M ohm resistor in series with RA0. kindly tell me how should i get the voltage sample form 220V AC line feed it into the ADC of PIC and display the correct value on LCD screen. i need circuit diagram of voltage sample circuit and a little code for that.

any help will be much appreciated.

thanking you all in anticipation.

I want to measure the AC line voltages 220V using pin RA5 of Pic16F877A, and display it on LCD Screen. kindly help me with circuit diagram and code. i also studied the mikrochip application note AN521 bu't cant get any specifice solution. they just add a 5M ohm resistor in series with RA0. kindly tell me how should i get the voltage sample form 220V AC line feed it into the ADC of PIC and display the correct value on LCD screen. i need circuit diagram of voltage sample circuit and a little code for that.

any help will be much appreciated.

thanking you all in anticipation.