DeepOne

Advanced Member level 2

- Joined

- Feb 26, 2011

- Messages

- 632

- Helped

- 99

- Reputation

- 200

- Reaction score

- 100

- Trophy points

- 28

- Location

- 45N39E, Russia

- Activity points

- 0

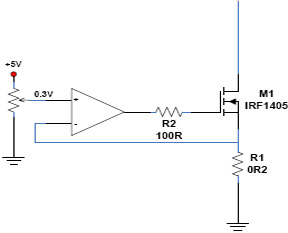

no, but possible do experiments with feedback and overcurrent sections of pwm controller

As far as i know, the lazer diodes use built-in photosensors for restriction of power and only current regulations may be is not enough.

Or can be there is sense to do current regulation on MCU base which can expose respective code on IRU (or similar PWM) input pins.

As far as i know, the lazer diodes use built-in photosensors for restriction of power and only current regulations may be is not enough.

Or can be there is sense to do current regulation on MCU base which can expose respective code on IRU (or similar PWM) input pins.

Last edited: