powersys

Advanced Member level 1

Hi,

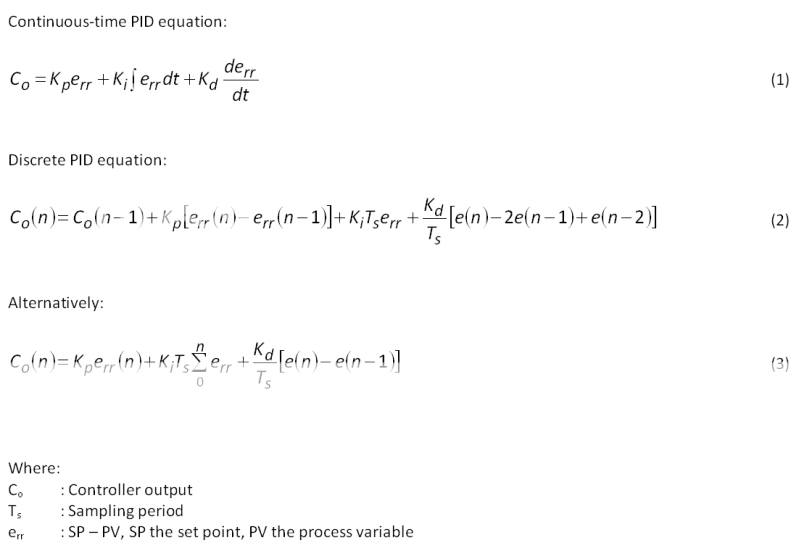

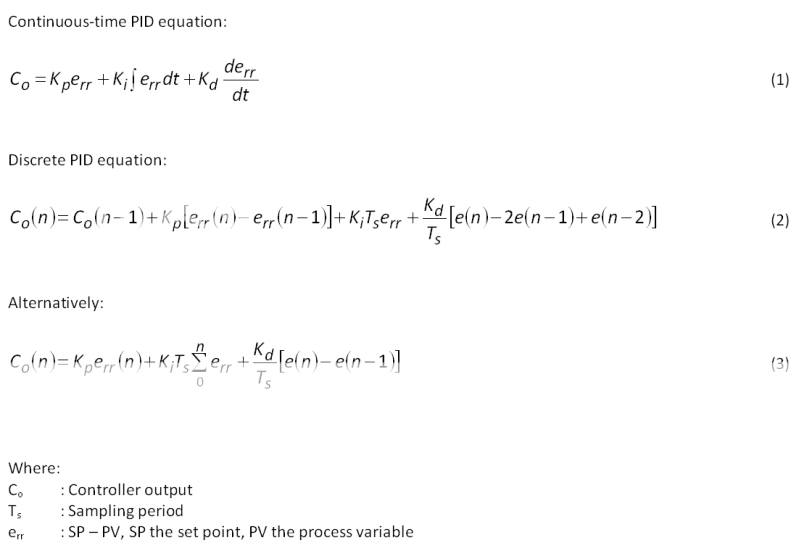

I have implemented the discrete PID controller, i.e. Eq.(2), in Texas C31 DSP. I wish to implement anti-windup as well. Kindly advise how to add anti-windup to the discrete PID controller.

By the way, do you think DSP implementation of Eq.(2) and Eq.(3) will give similar system performance?

Thanks.

I have implemented the discrete PID controller, i.e. Eq.(2), in Texas C31 DSP. I wish to implement anti-windup as well. Kindly advise how to add anti-windup to the discrete PID controller.

By the way, do you think DSP implementation of Eq.(2) and Eq.(3) will give similar system performance?

Thanks.