rajaram04

Advanced Member level 3

- Joined

- Jun 17, 2012

- Messages

- 871

- Helped

- 6

- Reputation

- 12

- Reaction score

- 5

- Trophy points

- 1,298

- Location

- earth

- Activity points

- 7,687

hello sir

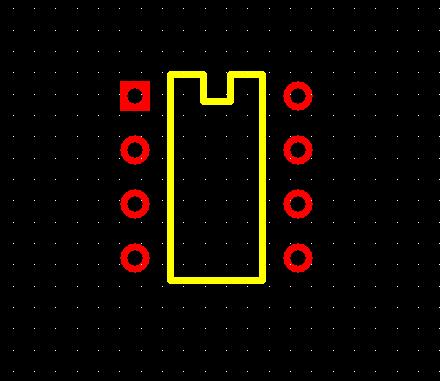

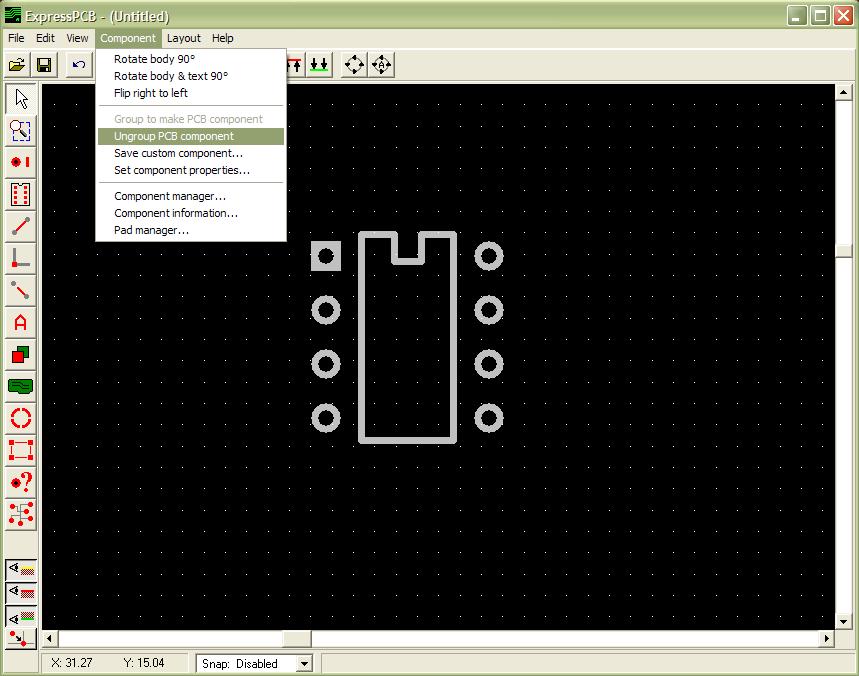

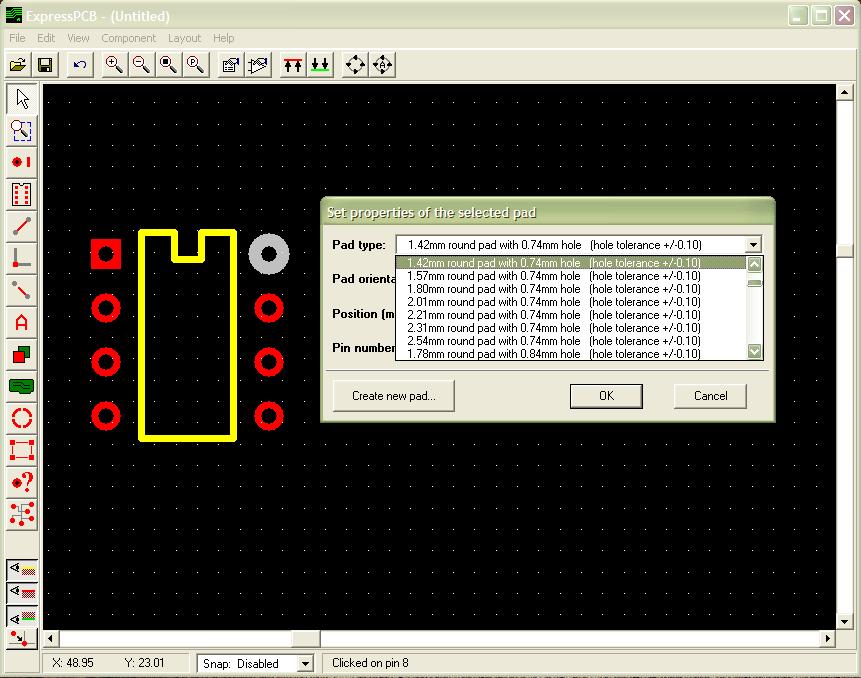

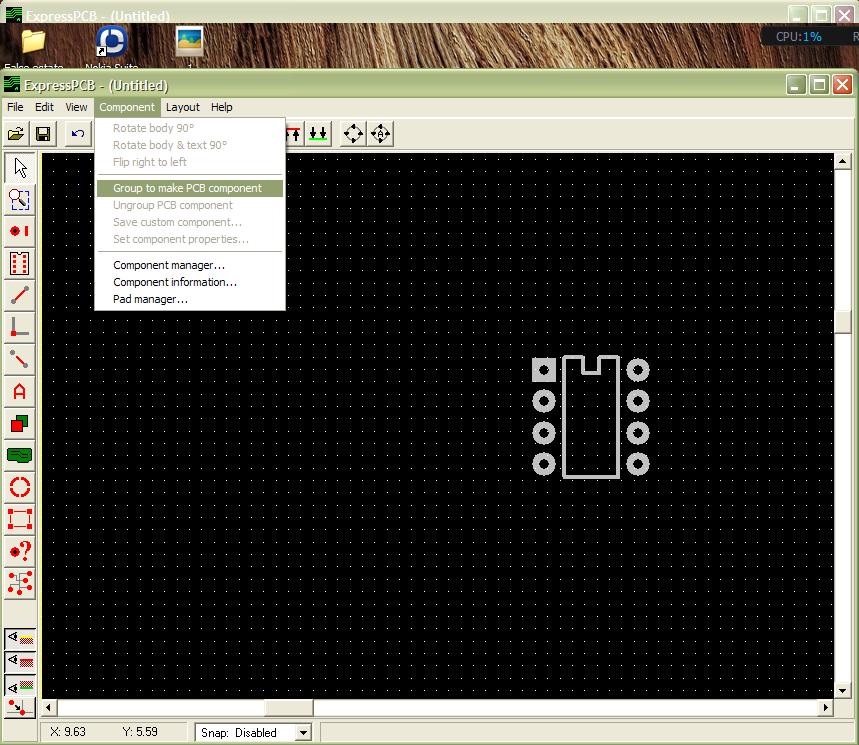

i want to make a clear desiging of my circuit on a pcb , so i want to make the design not only with copper platings connectors but with hole explanation there too , i designed in some softs but not able to mark holes there , actually i want to specify hole location so as to make ICs & other deligate components to be install properly in place with no stress , i jst want to make it like as we find them in market . Not much perfection clearity but needs connecting plates & holes simply , Too i ll make it with a simple chemical process further but please let me get a simple soft first

i want to make a clear desiging of my circuit on a pcb , so i want to make the design not only with copper platings connectors but with hole explanation there too , i designed in some softs but not able to mark holes there , actually i want to specify hole location so as to make ICs & other deligate components to be install properly in place with no stress , i jst want to make it like as we find them in market . Not much perfection clearity but needs connecting plates & holes simply , Too i ll make it with a simple chemical process further but please let me get a simple soft first