T

treez

Guest

We are looking for a 48VDC (25W) Axial fan to cool our electronics with. We need it to look like a resistive load so that we can supply it from a small value ceramic capacitor as we do not want any electrolytic caps on the PCB.

As you know, many BLDC fan motors do not actually have “high frequency PWM” controlled fan coil current, -rather they simply have “commutation PWM’’ which switches from one coil to the next in order to spin the fan.

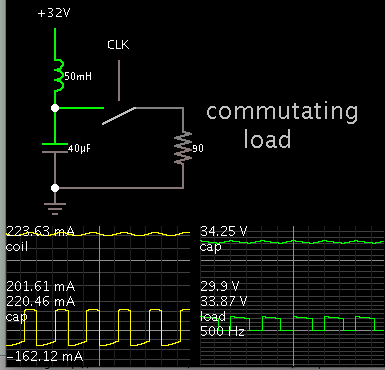

As you know, if there is no “high frequency PWM” acting on the fan coils, then the fan coils can resonate with the supply capacitor if the supply capacitor is not big enough, and to be that big the supply capacitor has to be an electrolytic one, which we do not want. As you know, if the fan coil commutation period is greater than the LC resonant frequency of the fan coil inductance and supply capacitor, then the resonance causes problems for driving the fan.

Do you know of any fans which have the high frequency PWM’ing of the fan coils such that the fan coils effectively look like resistive loads from the supply capacitors point of view?

As you can see on page 3 of the following, the current in most brushless dc fans is highly resonant, this causes much ripple current in the supply capacitor...the resonant appearance to the waveform that you see on page 3, is actually the fan coil inductance resonating with the supply capacitance.

https://www.nmbtc.com/pdf/engineering/cooling_fan_behavior.pdf

As you know, many BLDC fan motors do not actually have “high frequency PWM” controlled fan coil current, -rather they simply have “commutation PWM’’ which switches from one coil to the next in order to spin the fan.

As you know, if there is no “high frequency PWM” acting on the fan coils, then the fan coils can resonate with the supply capacitor if the supply capacitor is not big enough, and to be that big the supply capacitor has to be an electrolytic one, which we do not want. As you know, if the fan coil commutation period is greater than the LC resonant frequency of the fan coil inductance and supply capacitor, then the resonance causes problems for driving the fan.

Do you know of any fans which have the high frequency PWM’ing of the fan coils such that the fan coils effectively look like resistive loads from the supply capacitors point of view?

As you can see on page 3 of the following, the current in most brushless dc fans is highly resonant, this causes much ripple current in the supply capacitor...the resonant appearance to the waveform that you see on page 3, is actually the fan coil inductance resonating with the supply capacitance.

https://www.nmbtc.com/pdf/engineering/cooling_fan_behavior.pdf

Last edited by a moderator: