rocky79

Member level 5

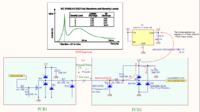

I have been looking for a level 4 ESD pin protection on microcontroller pin( pic16f1503).

The micro digital input pin is used to measure pulses between 50us to 200us.

Do you think a circuit like this would work?

R=500 ohms and

C=0.01uF

VESD=V0=15kv ( Level 4)

Vc=V0(1-e^(-t/RC))

Ic=(V0/R)*e^(-t/RC)

the RC filter will take 1.67uS to charge to 5v however the deadly spikes only last 10’s of nano-seconds.

The initial spike current at t=0 is V0/R=(15kv/500)=30 amps.

In order to conduct this damaging current away from the protected component I added a TVS diode in parallel with the RC.

What do you think about this TVS from littlefuse part# SD05C it has 5v reverse working voltage and clamp at 14.5v 10amps?

Any other suggestions will be appreciated.

**broken link removed**

The micro digital input pin is used to measure pulses between 50us to 200us.

Do you think a circuit like this would work?

R=500 ohms and

C=0.01uF

VESD=V0=15kv ( Level 4)

Vc=V0(1-e^(-t/RC))

Ic=(V0/R)*e^(-t/RC)

the RC filter will take 1.67uS to charge to 5v however the deadly spikes only last 10’s of nano-seconds.

The initial spike current at t=0 is V0/R=(15kv/500)=30 amps.

In order to conduct this damaging current away from the protected component I added a TVS diode in parallel with the RC.

What do you think about this TVS from littlefuse part# SD05C it has 5v reverse working voltage and clamp at 14.5v 10amps?

Any other suggestions will be appreciated.

**broken link removed**

Last edited: