alexan_e

Administrator

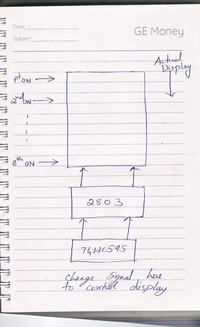

What king of multiplexing are you doing because the way that the circuit is wired I would expect to turn on

Row1 (and all columns of all display)

Row2

Row3

Row4

Row5

Row6

Row7

Row8

and then again from row 1

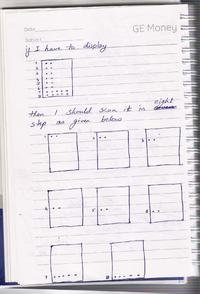

What you describe is

turn on all row/column of display 1

turn on all row/column of display 2

turn on all row/column of display 3

turn on all row/column of display 4

turn on all row/column of display 5

turn on all row/column of display 6

turn on all row/column of display 7

turn on all row/column of display 8

and then from start

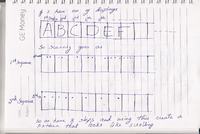

This way you need a faster multiplexing rate 1/16 but less current, in the first way you need lower rate 1/8 and higher current, it is up to you but I don't understand why did you use the individual anode transistors if you are going to turn on/off all 8 of them at the same time(the second way)?

Alex

Row1 (and all columns of all display)

Row2

Row3

Row4

Row5

Row6

Row7

Row8

and then again from row 1

What you describe is

turn on all row/column of display 1

turn on all row/column of display 2

turn on all row/column of display 3

turn on all row/column of display 4

turn on all row/column of display 5

turn on all row/column of display 6

turn on all row/column of display 7

turn on all row/column of display 8

and then from start

This way you need a faster multiplexing rate 1/16 but less current, in the first way you need lower rate 1/8 and higher current, it is up to you but I don't understand why did you use the individual anode transistors if you are going to turn on/off all 8 of them at the same time(the second way)?

Alex