Mtech1

Junior Member level 1

Hi,

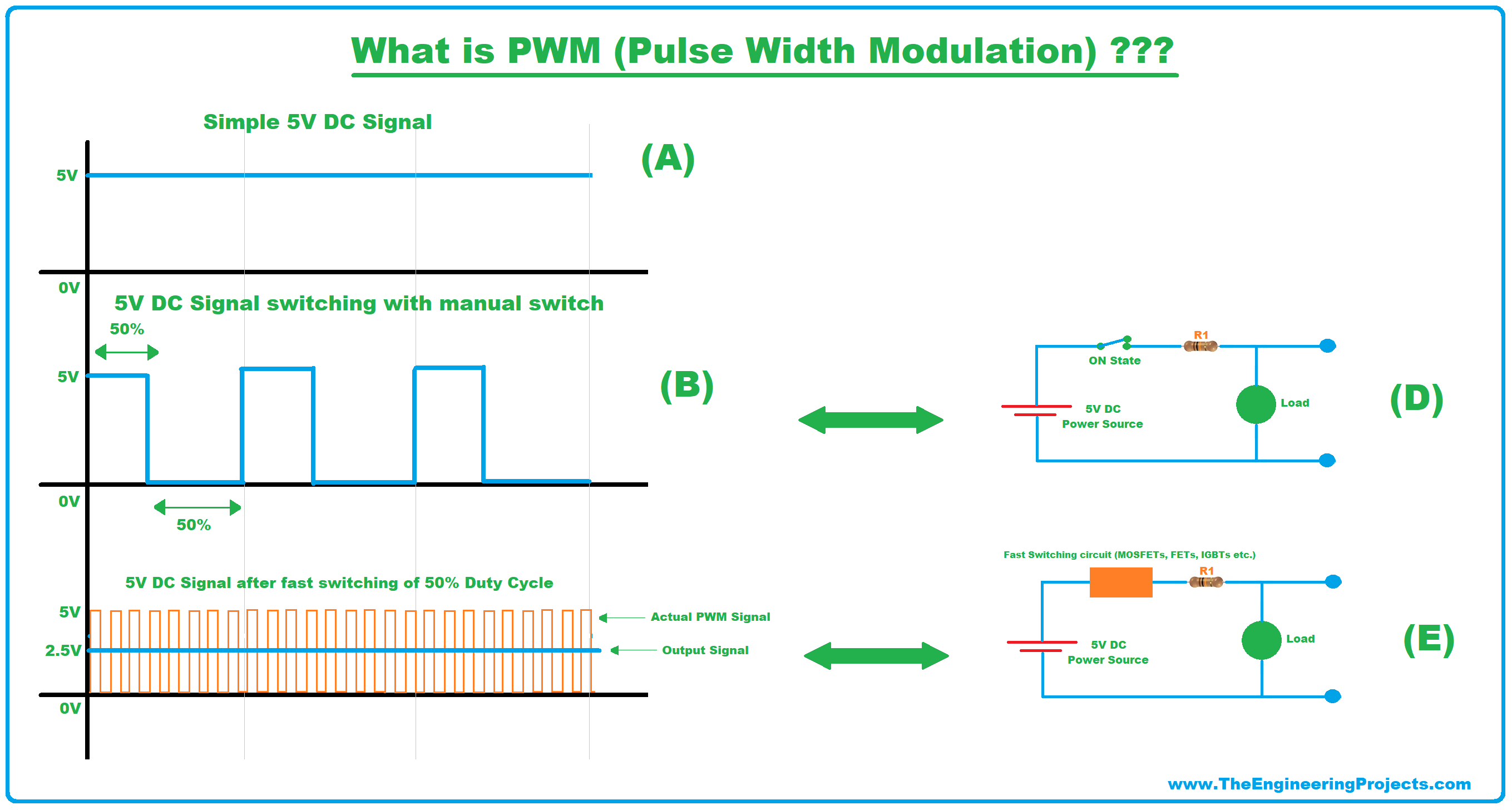

I've come across the concept of controlling LED brightness with PWM (Pulse Width Modulation) using a microcontroller. I looked that adjusting the duty cycle from 0% to 100% is involved in controlling LED brightness. However, I'm looking a clear understanding of the principles behind it, particularly the role of the timer. Researching several sources, I'm still not entirely clear on this.

circuitdigest.com

circuitdigest.com

Thank you in advance.

I've come across the concept of controlling LED brightness with PWM (Pulse Width Modulation) using a microcontroller. I looked that adjusting the duty cycle from 0% to 100% is involved in controlling LED brightness. However, I'm looking a clear understanding of the principles behind it, particularly the role of the timer. Researching several sources, I'm still not entirely clear on this.

Generating PWM using PIC Microcontroller with MPLAB and XC8

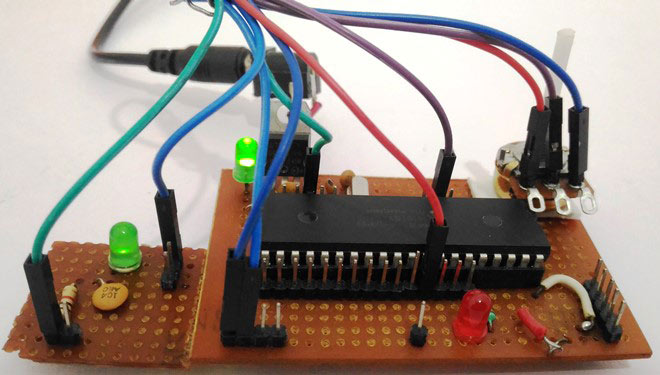

In this tutorial we learn how to generate PWM signals using PIC PIC16F877A. PIC MCU has a special module called Compare Capture module (CCP) which can be used to generate PWM signals.

Thank you in advance.