bloke203

Member level 1

Dear All

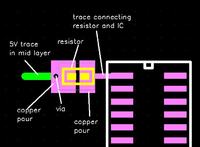

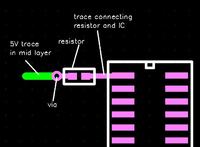

I am really in an awkward position. My employer ask me to place a 1206 package resistor between the 5V track and the pin X to the IC. So I did. We are not using any seperate ground plane and power plane And, we do machine soldering. And there is always a solder mask to the PCB. There was a 0.25mm width of 5V track. I am not been told that how much current is flowing.

The 5V track comes thru the second layer of the PCB board

But he is saying that I should have to place a thermal relief around a resistor. If I am right, thermal relief should need a little bit copper around the resistor pads and connect them to the ground (with via hole). If I did then the 5V track and the ground via can make it SHORT circuit.

IF I do it differently like instead of connecting to the ground, if I connect the via to the 5V then I am worried, what would be the purpose of it?

Second, If PCB layout guy not been told how much current is flowing and the width of the track is small then how would the layout guy know to place a thermal relief?

Can anypne help me?

Thanks

I am really in an awkward position. My employer ask me to place a 1206 package resistor between the 5V track and the pin X to the IC. So I did. We are not using any seperate ground plane and power plane And, we do machine soldering. And there is always a solder mask to the PCB. There was a 0.25mm width of 5V track. I am not been told that how much current is flowing.

The 5V track comes thru the second layer of the PCB board

But he is saying that I should have to place a thermal relief around a resistor. If I am right, thermal relief should need a little bit copper around the resistor pads and connect them to the ground (with via hole). If I did then the 5V track and the ground via can make it SHORT circuit.

IF I do it differently like instead of connecting to the ground, if I connect the via to the 5V then I am worried, what would be the purpose of it?

Second, If PCB layout guy not been told how much current is flowing and the width of the track is small then how would the layout guy know to place a thermal relief?

Can anypne help me?

Thanks