danismith

Member level 2

- Joined

- May 29, 2013

- Messages

- 47

- Helped

- 0

- Reputation

- 0

- Reaction score

- 0

- Trophy points

- 1,286

- Activity points

- 1,584

hi,

can anyone clear my doubt,

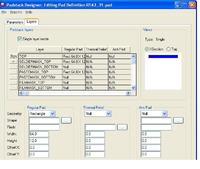

i have created a pad of

drill hole 40mm,(no tolorance)

regular pad 80 mm,

anti pad 85mm,

thermal pad 90mm.

then i have applied

80 mm soldermask,

80 mm paste mask.

is this creation is wright or wrong?

when i gave the board for manufacturing ,they asked me to give more solder mask ,

now, what i should do?????

can anyone clear my doubt,

i have created a pad of

drill hole 40mm,(no tolorance)

regular pad 80 mm,

anti pad 85mm,

thermal pad 90mm.

then i have applied

80 mm soldermask,

80 mm paste mask.

is this creation is wright or wrong?

when i gave the board for manufacturing ,they asked me to give more solder mask ,

now, what i should do?????