Altazi

Newbie level 3

Hello All,

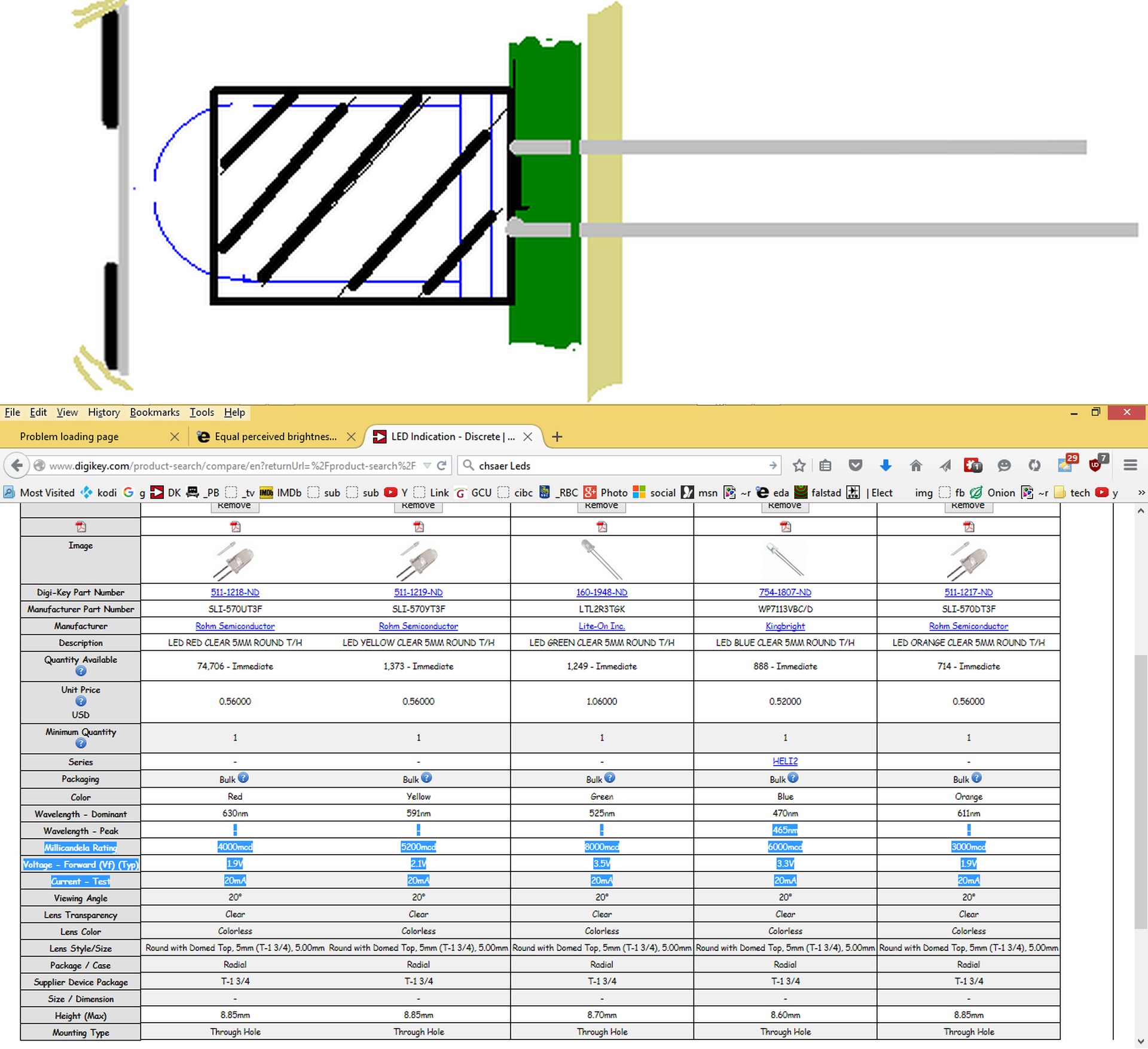

I am creating a front panel which uses discrete LED indicators – red, orange, yellow, green, and blue. Looking on Digi-Key (doesn’t everyone?) at the LEDs shows their luminous intensity in millicandelas (mcd), along with their dominant and peak wavelengths.

I would like all of the different colors of LEDs to appear to have the same perceived brightness, and haven’t had any success in searching for this. I know the human eye doesn’t respond equally to all wavelengths of light, so what do I do next? Would 100mcd LEDs in all colors appear to have the same brightness? Or should I normalize them based on the human eye response?

A separate, but related question: How bright is a 100mcd LED? Is it bright enough to be easily visible when located behind a polycarbonate overlay in muted sunlight? 400mcd? The mcd values are all over the map. I’d like the LEDs to be readily visble, but not painfully bright.

I would prefer to calculate the results rather than just buy a bunch of differently-rated LEDs and empirically determine what is equal brightness. Thanks in advance!

I am creating a front panel which uses discrete LED indicators – red, orange, yellow, green, and blue. Looking on Digi-Key (doesn’t everyone?) at the LEDs shows their luminous intensity in millicandelas (mcd), along with their dominant and peak wavelengths.

I would like all of the different colors of LEDs to appear to have the same perceived brightness, and haven’t had any success in searching for this. I know the human eye doesn’t respond equally to all wavelengths of light, so what do I do next? Would 100mcd LEDs in all colors appear to have the same brightness? Or should I normalize them based on the human eye response?

A separate, but related question: How bright is a 100mcd LED? Is it bright enough to be easily visible when located behind a polycarbonate overlay in muted sunlight? 400mcd? The mcd values are all over the map. I’d like the LEDs to be readily visble, but not painfully bright.

I would prefer to calculate the results rather than just buy a bunch of differently-rated LEDs and empirically determine what is equal brightness. Thanks in advance!