darcyrandall2004

Full Member level 1

- Joined

- Feb 1, 2009

- Messages

- 97

- Helped

- 3

- Reputation

- 6

- Reaction score

- 0

- Trophy points

- 1,286

- Location

- Perth, WA, Australia

- Activity points

- 2,099

Hello,

In an effort to improve the accuracy of my RF design, I have created a PCB for measuring 0805 smt components in a series and shunt configuration. See below.

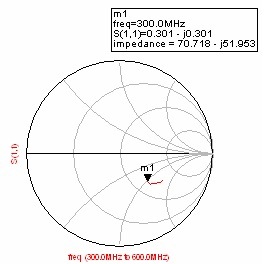

Using momentum I created a layout component of the PCB. I measured the S parameters of a 22ohm resistor placed between port 1 and 2 using the VNA. I then deEmbed the component from the PCB using ADS.

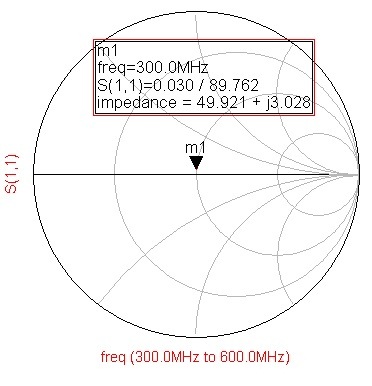

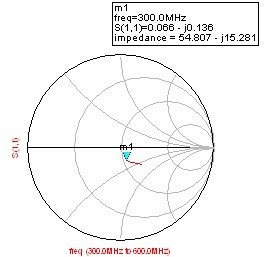

I would expect to read an input impedance of 72 ohms when a 22ohm series resistor is placed between port 1 and 2 of the VNA. Instead I measured roughly 72 ohms but strangely a series 10pF capacitance.

Does this value of 10pF parasitic series capacitance sound correct? If this 10 pF parasitic capacitance is always present then it will severly limit the choice of series components I use.

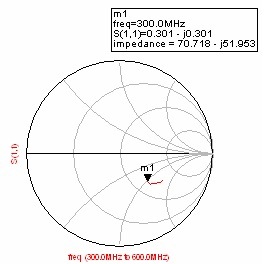

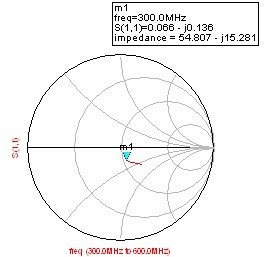

Like wise a shunt 47ohm resitor measured with 1 port of the VNA shows a 35pF series capacitance parasitic. I would have expected a parasitic series inductance due to the via between the resistor and the ground plane.

Do these results sound correct?

Note: My pcb is 0.8mm FR4 with 1.4mm wide tracks, 35um thick copper and a complete ground plane on one side. (ie characteristic impedance of 50ohm)

Thank you

In an effort to improve the accuracy of my RF design, I have created a PCB for measuring 0805 smt components in a series and shunt configuration. See below.

Using momentum I created a layout component of the PCB. I measured the S parameters of a 22ohm resistor placed between port 1 and 2 using the VNA. I then deEmbed the component from the PCB using ADS.

I would expect to read an input impedance of 72 ohms when a 22ohm series resistor is placed between port 1 and 2 of the VNA. Instead I measured roughly 72 ohms but strangely a series 10pF capacitance.

Does this value of 10pF parasitic series capacitance sound correct? If this 10 pF parasitic capacitance is always present then it will severly limit the choice of series components I use.

Like wise a shunt 47ohm resitor measured with 1 port of the VNA shows a 35pF series capacitance parasitic. I would have expected a parasitic series inductance due to the via between the resistor and the ground plane.

Do these results sound correct?

Note: My pcb is 0.8mm FR4 with 1.4mm wide tracks, 35um thick copper and a complete ground plane on one side. (ie characteristic impedance of 50ohm)

Thank you