Iman12

Newbie level 6

Hi all,

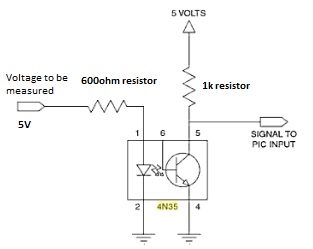

I've encountered a problem. I've tried to set the input current to the opto by using 5V and 600 ohm resistor, resulting less than 10mA input current. On the output side, I have put the voltage to 5V and resistor as 1k. It outputs fine, however, when I decrease the input voltage the output voltage increases. Is the opto reverse biased? Thanks all.

I've encountered a problem. I've tried to set the input current to the opto by using 5V and 600 ohm resistor, resulting less than 10mA input current. On the output side, I have put the voltage to 5V and resistor as 1k. It outputs fine, however, when I decrease the input voltage the output voltage increases. Is the opto reverse biased? Thanks all.