israel7732

Member level 3

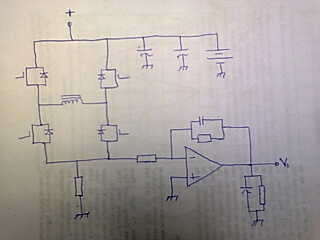

hi. i was told that an h-bridge could be used to boost charge inverter battery at constant current by varying the duty cycle of pulsing the bottom two mosfets. please how could the the charging current be measured and used as a feed back to the micro controller.