Tahmid

Advanced Member level 6

- Joined

- Jun 17, 2008

- Messages

- 4,756

- Helped

- 1,798

- Reputation

- 3,588

- Reaction score

- 1,656

- Trophy points

- 1,413

- Location

- Berkeley, California

- Activity points

- 30,584

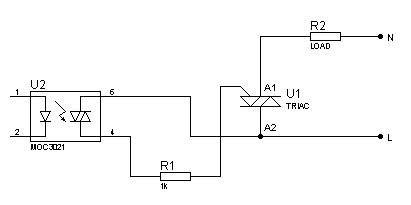

Thanks for pointing that out. I didn't know about the symbol. Anyways, the circuits above should work. :smile: I'll put up a fixed diagram.

Last edited: