Janecheck

Newbie level 5

Hello,

I am getting distored signal on HO output of my IR2110 driver.

I connected my IR2110 driver to a pair of two n - channel IRFP250 MOSFETs (no load) same as shown in data sheet.

I did not add the capacitor between drain of high side MOSFET, and source of low side MOSFET.

Picture 1 The way I wired the circuit (but without capacitor on the right side of the MOSFETs)

I used:

Picture 2 Setup

I supplied it with a 12V DC and used Arduino Uno as square wave signal source.

Arduino code

Then I measured LIN, LO and HIN, HO with oscilloscope. Here are the measurments:

LO (top) & LIN (bottom)

Picture 3 Signals from LO (top) and LIN (bottom)

It looks good.

HO (top) & HIN (bottom)

Picture 4 Signals from HO (top) & HIN (bottom)

As we can see the signal from HO is distored and I don't know why. What might be the issue?

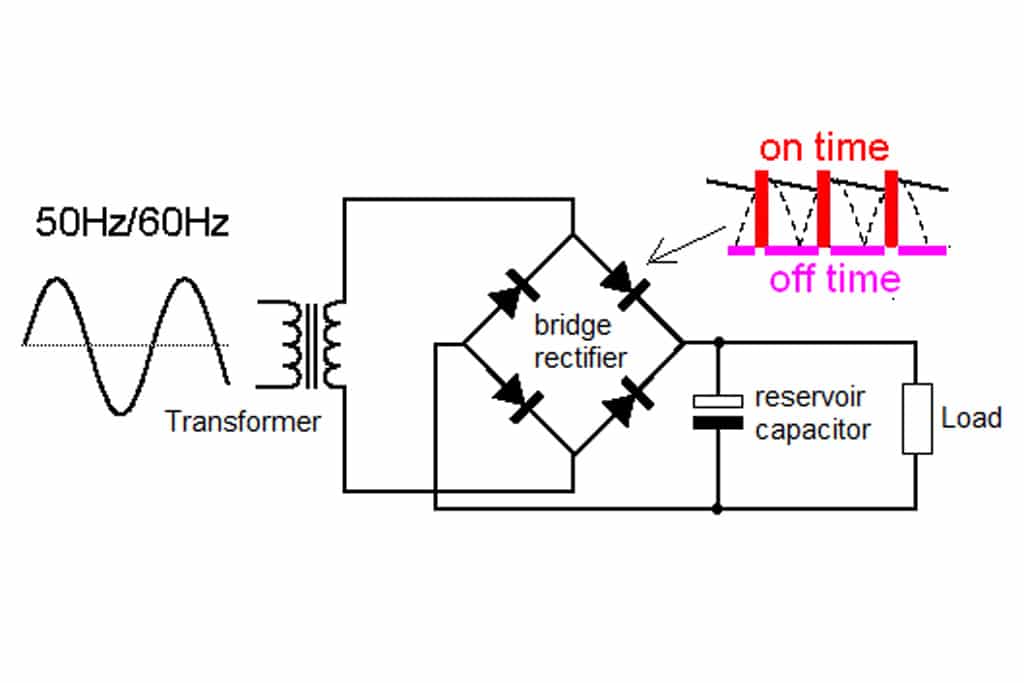

Is it because I picked wrong capacitor between Vb and Vs? If yes then how to choose the right capacitor?

I am trying to make 3 - phase inverter. At first for testing purposes only I wanted to control the speed of BLDC motor but after wiring it up it had quite a big problem to spin (it stared spinning after I pushed it a bit) and also one of six MOSFETs got hor quite fast (he is okay he just heats pretty quickly and this was strange for me). Now after measuring with oscilloscope I believe that the distorted HO signal was the issue.

Please help me.

I am getting distored signal on HO output of my IR2110 driver.

I connected my IR2110 driver to a pair of two n - channel IRFP250 MOSFETs (no load) same as shown in data sheet.

I did not add the capacitor between drain of high side MOSFET, and source of low side MOSFET.

Picture 1 The way I wired the circuit (but without capacitor on the right side of the MOSFETs)

I used:

- 3 x 100 nF ceramic capacitors

- 2 x 100 ohm resistor

- 1 x UF4007 diode

Picture 2 Setup

I supplied it with a 12V DC and used Arduino Uno as square wave signal source.

Arduino code

Code:

digitalWrite(3, HIGH);

digitalWrite(5, LOW);

delay(5);

digitalWrite(3, LOW);

digitalWrite(5, HIGH);

delay(5);Then I measured LIN, LO and HIN, HO with oscilloscope. Here are the measurments:

LO (top) & LIN (bottom)

Picture 3 Signals from LO (top) and LIN (bottom)

It looks good.

HO (top) & HIN (bottom)

Picture 4 Signals from HO (top) & HIN (bottom)

As we can see the signal from HO is distored and I don't know why. What might be the issue?

Is it because I picked wrong capacitor between Vb and Vs? If yes then how to choose the right capacitor?

I am trying to make 3 - phase inverter. At first for testing purposes only I wanted to control the speed of BLDC motor but after wiring it up it had quite a big problem to spin (it stared spinning after I pushed it a bit) and also one of six MOSFETs got hor quite fast (he is okay he just heats pretty quickly and this was strange for me). Now after measuring with oscilloscope I believe that the distorted HO signal was the issue.

Please help me.