KhaledOsmani

Full Member level 6

Hello dears,

This website is such a magnificent job. Great effort, in a smart way with interactions of great experienced members.

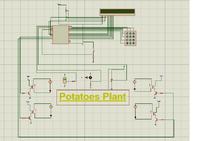

I`m doing a small project, concerning automation/control/monitoring about a green-house.

I`m using a PIC18F4520.

I`m coding in Assembly.

I'm using as output an 2*40 LCD (LMB402CFC): as an interface for the user.

The questions are as follows:

*What does the output of square blocks sequence on the LCD means? solutions?

*At first attempt the circuit ran good, but I made small changes in connections (no Short Circuit) And noticed on the oscilloscope a very high amperage (I = 0.8A) for 5V DC for the PIC and the LCD. Why?

*How sensitive a microcontroller is, and for how much I must be careful with it (beside temperature storage)?

Thanks,

This website is such a magnificent job. Great effort, in a smart way with interactions of great experienced members.

I`m doing a small project, concerning automation/control/monitoring about a green-house.

I`m using a PIC18F4520.

I`m coding in Assembly.

I'm using as output an 2*40 LCD (LMB402CFC): as an interface for the user.

The questions are as follows:

*What does the output of square blocks sequence on the LCD means? solutions?

*At first attempt the circuit ran good, but I made small changes in connections (no Short Circuit) And noticed on the oscilloscope a very high amperage (I = 0.8A) for 5V DC for the PIC and the LCD. Why?

*How sensitive a microcontroller is, and for how much I must be careful with it (beside temperature storage)?

Thanks,