salah_edu

Junior Member level 1

Hi All,

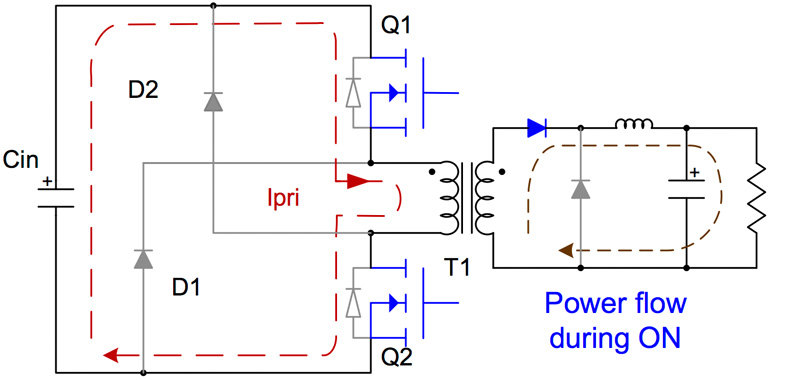

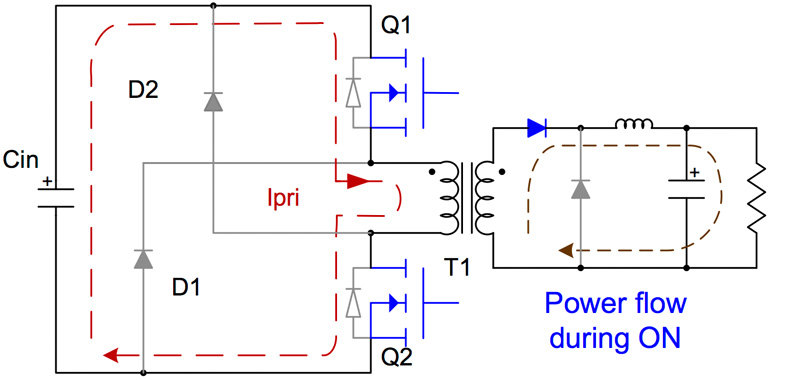

i want to build 5kw welder inverter , so i want to choose a ferrite core for my transformer , the core is a toroid with T63 mm out diameter and 38mm in diameter and 25mm thick and without a gap (MnZn PC40 material), i want to use it in two swich forward converter topology, so is it ok to use this core in this topology wothout a gap , or it must contain a gap ?

Thank you

i want to build 5kw welder inverter , so i want to choose a ferrite core for my transformer , the core is a toroid with T63 mm out diameter and 38mm in diameter and 25mm thick and without a gap (MnZn PC40 material), i want to use it in two swich forward converter topology, so is it ok to use this core in this topology wothout a gap , or it must contain a gap ?

Thank you