bogusmeister

Junior Member level 2

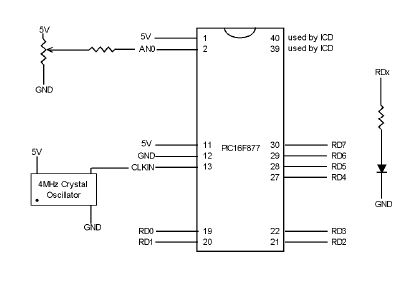

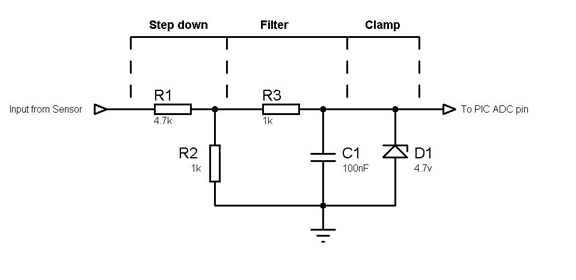

Im using a QTR-1A reflectance sensor (analog) as an input for PIC16F877.. im kinda new in using this PIC, i just used it because of its built-in ADC. i have tried the sample assembly program of ADC using a potentiometer and it worked. but when i replace it with the reflectance sensor. im not getting any output.. pls help me. thanks in advance