Rahul Ahuja

Newbie level 6

- Joined

- Nov 18, 2012

- Messages

- 14

- Helped

- 0

- Reputation

- 0

- Reaction score

- 0

- Trophy points

- 1,281

- Activity points

- 1,379

Hi

This is Rahul Ahuja

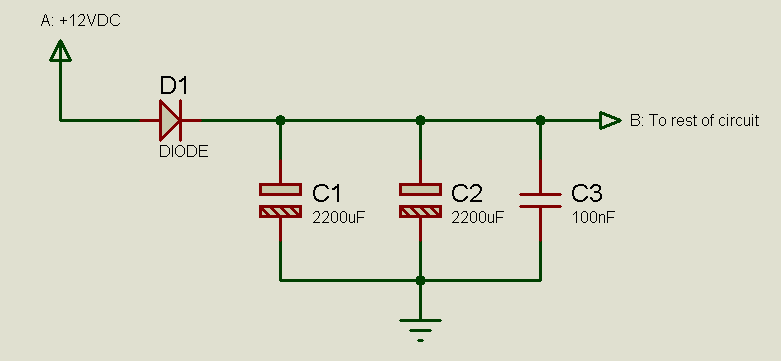

I am driving 0.5 hp 230VAC blower motor with 8051 using 10A relay. Everything is going ok but i am facing one problem. whenever relay gets ON it starts the motor but suddenly it resets the controller. I am using different power supply for controller and motor. Can any one tell why it is happening ????

This is Rahul Ahuja

I am driving 0.5 hp 230VAC blower motor with 8051 using 10A relay. Everything is going ok but i am facing one problem. whenever relay gets ON it starts the motor but suddenly it resets the controller. I am using different power supply for controller and motor. Can any one tell why it is happening ????