smarty88

Newbie level 3

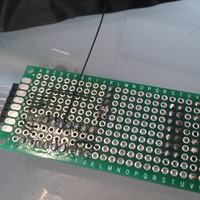

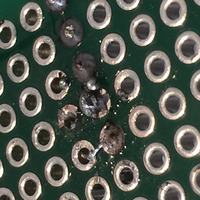

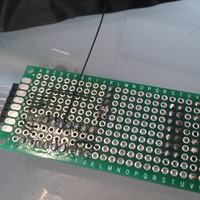

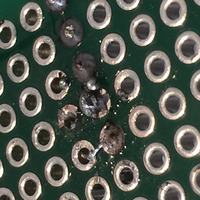

I've been soldering for over 30 years and not experienced this problem before, bought some solder from ebay 60 tin/38 lead / 2 resin flux. also have another composition 63/37 supposedly with flux also. every time I add the solder to heated component and pcb pad it simply turns into flakes. no matter what temperature I cannot get the solder to pool successfully each time instead it crumbles and flakes away. My iron is set at 370c however I have tried lower (will not melt) and higher to about 400c with same issue. It's very frustrating and I cannot seem to find a replicate of this problem on any searches. I've wasted countless hours and components now trying to get this solder (from ebay) to work without success. Photos attached. Any advice would be greatly appreciated, thanks !