Man68

Newbie level 6

Hi all,

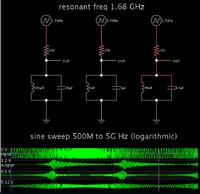

I am designing a 5th order passive BPF (LC) with center frequency of 1.67 GHz and 300 MHz bandwidth. After getting the values for the LC components and simulating in ADS, input/output return losses are quite high (>-10 dB). How can I improve S11 to be at least less than -15 dB?

How I can use the smith chart as the operation frequency BW is too high?!

Thanks

I am designing a 5th order passive BPF (LC) with center frequency of 1.67 GHz and 300 MHz bandwidth. After getting the values for the LC components and simulating in ADS, input/output return losses are quite high (>-10 dB). How can I improve S11 to be at least less than -15 dB?

How I can use the smith chart as the operation frequency BW is too high?!

Thanks