steve23h

Newbie level 5

To give a brief background of what I am trying to do keeping it as simple as I can:

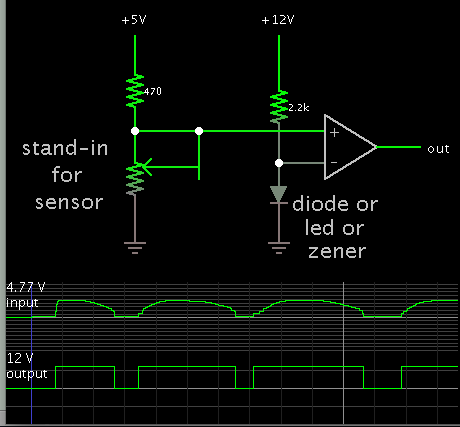

I build machines that are driven by 5VDC photosensor's among other components. What I am trying to accomplish is taking the 5 volt sensor signal, which is driven by a logic board, and write a program using that signal. Currently I use a DL-06 PLC with a CMORE touchscreen. I have my program written already now I need my signal to cooperate in order to make my program work. So far I have tried a 5VDC coil mechanical relay and a solid state relay and they have both not given me the results I am looking for. Unfortunately I cannot take the signal straight from my sensor and activate my program because the PLC requires a 12-24 VDC input where my sensor only supplies 5 volts.

Now that is out of the way, I have landed on using a LM324 Single Supply Quad Amplifier IC. I have spoken to a rep from the company that makes this product and he assures me I will be able to make it work, I am just trying to get a little more information on how I can wire it.

Any help would be much appreciated. If there is any more information that is needed in order to assist me I would be more than happy to supply it.

Thank You

I build machines that are driven by 5VDC photosensor's among other components. What I am trying to accomplish is taking the 5 volt sensor signal, which is driven by a logic board, and write a program using that signal. Currently I use a DL-06 PLC with a CMORE touchscreen. I have my program written already now I need my signal to cooperate in order to make my program work. So far I have tried a 5VDC coil mechanical relay and a solid state relay and they have both not given me the results I am looking for. Unfortunately I cannot take the signal straight from my sensor and activate my program because the PLC requires a 12-24 VDC input where my sensor only supplies 5 volts.

Now that is out of the way, I have landed on using a LM324 Single Supply Quad Amplifier IC. I have spoken to a rep from the company that makes this product and he assures me I will be able to make it work, I am just trying to get a little more information on how I can wire it.

Any help would be much appreciated. If there is any more information that is needed in order to assist me I would be more than happy to supply it.

Thank You