Rajnaveen

Member level 2

- Joined

- May 11, 2014

- Messages

- 42

- Helped

- 0

- Reputation

- 0

- Reaction score

- 0

- Trophy points

- 6

- Activity points

- 307

hi friends

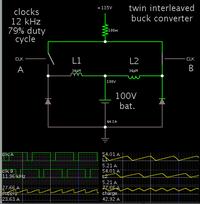

I am designing a 5KW buck converter for battery charging from solar . will you pease help me in design .

how to select the core .? and i want it to operate in DCM is it better .how much inductence is sufficient .

I am designing a 5KW buck converter for battery charging from solar . will you pease help me in design .

how to select the core .? and i want it to operate in DCM is it better .how much inductence is sufficient .