rakesh1987

Junior Member level 3

Hello all,

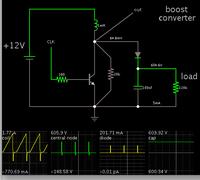

my igbt connected to boost converter is failing , when operated at light load and 600v, its rated for 1200V and 40A, I am expecting a voltage spike at the IGBt causing its failure ? please help me to solve it?

my igbt connected to boost converter is failing , when operated at light load and 600v, its rated for 1200V and 40A, I am expecting a voltage spike at the IGBt causing its failure ? please help me to solve it?