Raees

Junior Member level 2

- Joined

- Jun 6, 2013

- Messages

- 23

- Helped

- 0

- Reputation

- 0

- Reaction score

- 0

- Trophy points

- 1,281

- Activity points

- 1,471

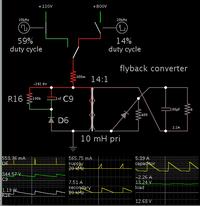

Hi everyone. I want to make a transformer myself. I using the following application note

my input voltage is similar that is in this application note, that is 130VDC to 800VDC.

output voltage = 12VDC 2Amp.

i tried to make myself by using the calculation, and it is working too but the problem i m facing is in snubber circuit. i have used 300 ohms and 20 Watts and they are heating like hell. i m sure there is leakage inductance. but how to reduce it? any one plz help.

my input voltage is similar that is in this application note, that is 130VDC to 800VDC.

output voltage = 12VDC 2Amp.

i tried to make myself by using the calculation, and it is working too but the problem i m facing is in snubber circuit. i have used 300 ohms and 20 Watts and they are heating like hell. i m sure there is leakage inductance. but how to reduce it? any one plz help.