Sajjadkhan

Full Member level 5

- Joined

- Sep 25, 2010

- Messages

- 307

- Helped

- 17

- Reputation

- 34

- Reaction score

- 16

- Trophy points

- 1,298

- Location

- Rawalpindi,Pakistan

- Activity points

- 4,199

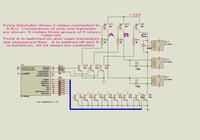

I need to make 24 fans controller. the board has a lcd display and few buttons for settings.

the main issue here is controller I/O pins and cost.

24 pins for fans (220v)

6 pins for lcd,

3 pins for buttons i.e. adjust, up, down ( for setting ON/OFF timer ).

i dont want to use 40 pin controller, 28 pin or less would be fine, then i would also be needing some port expansion method.

so throw me some ideas for a cheapest design possible to workout this problem, i need to make 500 boards with max profit margin.

the main issue here is controller I/O pins and cost.

24 pins for fans (220v)

6 pins for lcd,

3 pins for buttons i.e. adjust, up, down ( for setting ON/OFF timer ).

i dont want to use 40 pin controller, 28 pin or less would be fine, then i would also be needing some port expansion method.

so throw me some ideas for a cheapest design possible to workout this problem, i need to make 500 boards with max profit margin.