cwin

Newbie level 5

I've only recently started using HFSS and I've noticed that sometimes I get strange, unphysical fields and solutions.

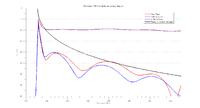

For example I'm simulating a transition of the TE11 mode in a circular waveguide into a TE10 mode in a rectangular waveguide. Below are two animations of this transition. The only difference between the two is the length of the taper, the first being 2mm in length and the second being 2.05mm in length. Simulations with taper length 2.1mm show a physically agreeable fields consistent with the 2mm simulation.

The circular waveguide has a radius of .46mm and transitions to a .9x.45mm rectangular waveguide.

The walls has conductivity 4.7e7 S/m.

My solution setup is:

Solution Freq: 250GHz

Adaptive Solution with Maximum number of Passes:6 with maximum delta S: 0.02.

I'm still learning the ropes of HFSS so let me know if there's something I completely over looked or if there's some tests I can run to pinpoint the cause of this strange effect.

For example I'm simulating a transition of the TE11 mode in a circular waveguide into a TE10 mode in a rectangular waveguide. Below are two animations of this transition. The only difference between the two is the length of the taper, the first being 2mm in length and the second being 2.05mm in length. Simulations with taper length 2.1mm show a physically agreeable fields consistent with the 2mm simulation.

The circular waveguide has a radius of .46mm and transitions to a .9x.45mm rectangular waveguide.

The walls has conductivity 4.7e7 S/m.

My solution setup is:

Solution Freq: 250GHz

Adaptive Solution with Maximum number of Passes:6 with maximum delta S: 0.02.

I'm still learning the ropes of HFSS so let me know if there's something I completely over looked or if there's some tests I can run to pinpoint the cause of this strange effect.