binaryninja

Member level 3

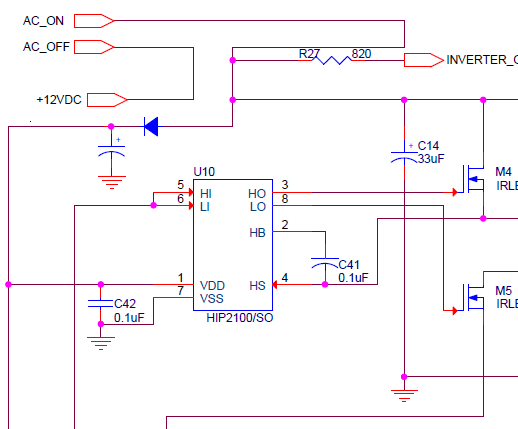

Hi all, I had posted a long time with a project for a 12V to 110VAC inverter. The front end that creates the high voltage needed by the H-bridge is a 2-switch forward converter. It takes in 12V and produces 155V, and it works up until it breaks. Looking at the schematic, C14 (Cin) blows and then U10 will burn up, also M4 appeared to fail at the same time. I'm trying to figure out why this is happening and what needs to be done to correct it. Any help will be greatly appreciated for I am swamped and do not have enough experience with power supplies. Thanks!

I realize you may need more info to make an accurate assessment. Please just ask me.

I realize you may need more info to make an accurate assessment. Please just ask me.

Attachments

Last edited: