T3STY

Full Member level 4

- Joined

- Apr 17, 2012

- Messages

- 239

- Helped

- 24

- Reputation

- 48

- Reaction score

- 24

- Trophy points

- 1,308

- Activity points

- 3,715

Hello everyone! It's good to be back after a long time

I need to design a nice switching power supply that will be used to power my electronic projects. I need a variable 15-0-15 dual voltage with per-line regulation (for example I want to be able to set -4V and +13V), and two fixed voltages of +5V and +3.3V (the 3.3V might be easily achievable from the +5V line). All lines should draw 1A current, but if it's possible to have more, say 2A, it would be nice yet not necessary.

I have studied** how switching power supplies work, the different topologies and design pros and cons, but I still don't think I'm able to proceed on my own on this task.

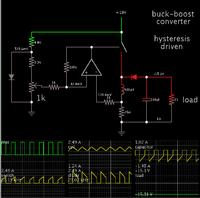

The starting power supply would be a notebook power supply with +19V 4A. Then I was thinking to use some LM2576 (and similar) switching ICs in flyback mode for the -15V supply, and in boost mode for the +15V and +5V supplies. The 3.3V line could be achieved with a 3.3V zener diode on the 5V line, but if you have any better suggestions they're welcome. Datasheet schematics are quite nice for fixed voltages but I don't know how to modify them for variable voltage output. Also, if possible, I would like to include some simple short circuit protection, just in case, but I haven't made any research on that yet.

Can you please help me with this?

** in particular **broken link removed** was the most useful I have found; it is in italian but you might understand the topics from the graphs.

I need to design a nice switching power supply that will be used to power my electronic projects. I need a variable 15-0-15 dual voltage with per-line regulation (for example I want to be able to set -4V and +13V), and two fixed voltages of +5V and +3.3V (the 3.3V might be easily achievable from the +5V line). All lines should draw 1A current, but if it's possible to have more, say 2A, it would be nice yet not necessary.

I have studied** how switching power supplies work, the different topologies and design pros and cons, but I still don't think I'm able to proceed on my own on this task.

The starting power supply would be a notebook power supply with +19V 4A. Then I was thinking to use some LM2576 (and similar) switching ICs in flyback mode for the -15V supply, and in boost mode for the +15V and +5V supplies. The 3.3V line could be achieved with a 3.3V zener diode on the 5V line, but if you have any better suggestions they're welcome. Datasheet schematics are quite nice for fixed voltages but I don't know how to modify them for variable voltage output. Also, if possible, I would like to include some simple short circuit protection, just in case, but I haven't made any research on that yet.

Can you please help me with this?

** in particular **broken link removed** was the most useful I have found; it is in italian but you might understand the topics from the graphs.