Albin George

Newbie level 4

- Joined

- May 4, 2014

- Messages

- 6

- Helped

- 0

- Reputation

- 0

- Reaction score

- 0

- Trophy points

- 1

- Activity points

- 56

i had an emergency lamp with a 6v, 4.5 AH lead acid battery & lighting a 14W, 220v CFL lamp, once i had dismantled it due to some charging problem. now i am trying to reassemble it, bt i accidentally cracked a wire from the board, and i am not getting from where it is came out (it is connected to a two way switch), so i need 2 assemble a new circuit i think.. can any body help me?? i need every details of making it, ('given i don't know anything about electronics, but i am good at soldering and all'  )

)

i think my requirements are,

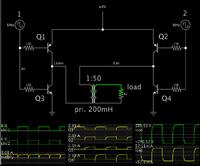

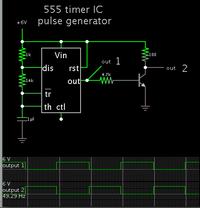

Convert 6V DC to AC current,

Amplify that AC to 220v (or 150 is enough i think) AC, i need no switches in the circuit.

also need to connect the battery charger to the same circuit,

i also need a circuit for the charger, i have 240V 50Hz AC power outlet,

:!::!::!: please help..

i think my requirements are,

Convert 6V DC to AC current,

Amplify that AC to 220v (or 150 is enough i think) AC, i need no switches in the circuit.

also need to connect the battery charger to the same circuit,

i also need a circuit for the charger, i have 240V 50Hz AC power outlet,

:!::!::!: please help..