johnny78

Full Member level 4

hi Guys

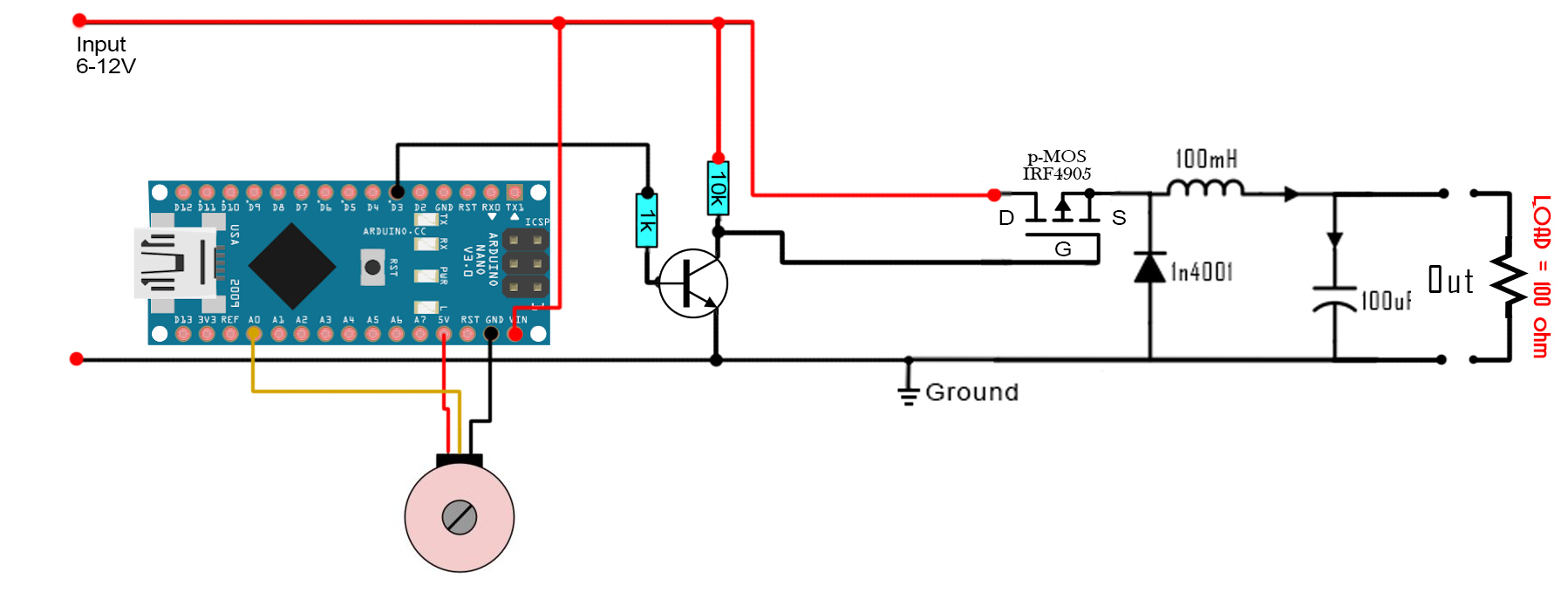

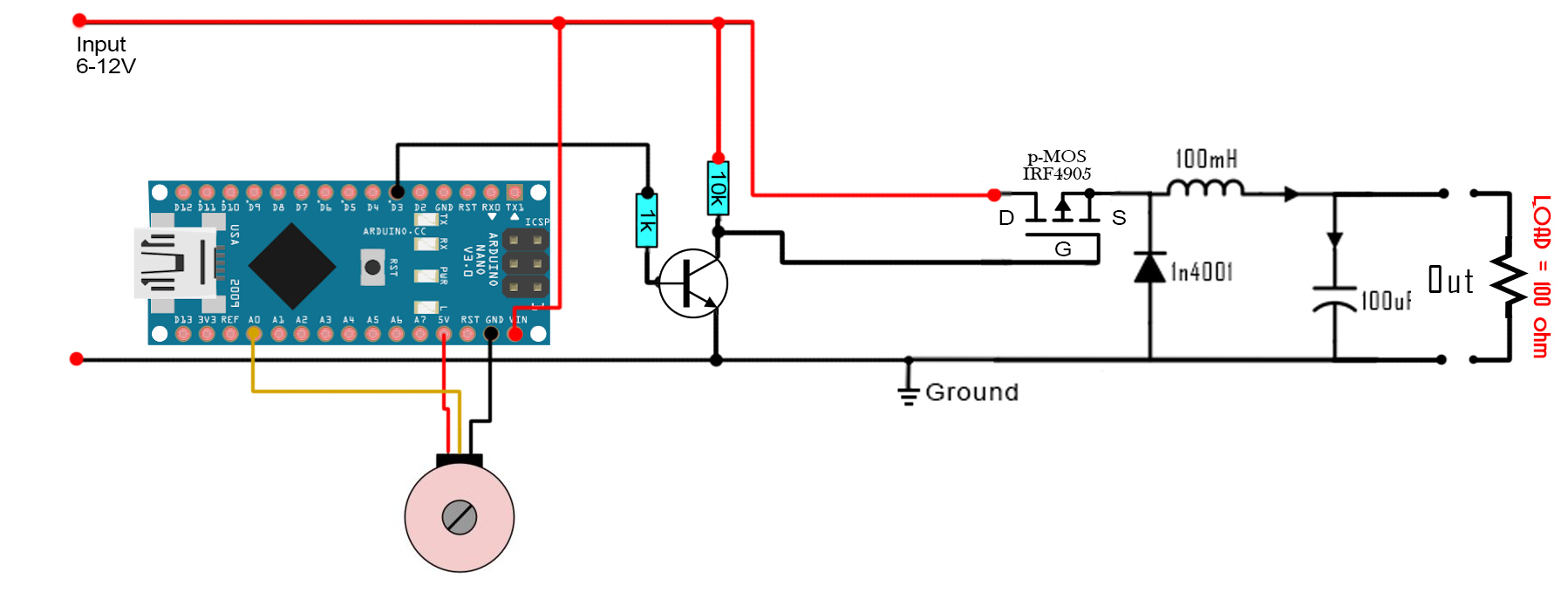

i need to use an MCU as a voltage regulator

read about pwm & checked for some projects on the net

would you check this please ?

first i think the mosfet is connected wrong way (or im wrong) ?

after correcting the connection(S is the input & D is the output) & upladed the simple pwm code to my UNO

& build the citcuit on 3A dc dc buck conveter which i have removed the lm2596 & connected the IRF4509 on it

but it didt work as a regulator

& tried to drive the mosfet with arduino uno with this code

i need to use an MCU as a voltage regulator

read about pwm & checked for some projects on the net

would you check this please ?

first i think the mosfet is connected wrong way (or im wrong) ?

after correcting the connection(S is the input & D is the output) & upladed the simple pwm code to my UNO

& build the citcuit on 3A dc dc buck conveter which i have removed the lm2596 & connected the IRF4509 on it

but it didt work as a regulator

& tried to drive the mosfet with arduino uno with this code

Code:

/*

* This is an example code for a BUCK converter circuit made with arduino

* I've used arduino NANO. We have to set the timer of the PWM on pin D3

* No feedback is connected here

* Subscribe: http://www.youtube.com/c/electronoobs

* webpage: http://www.electronoobs.com/eng_circuitos_tut10.php

*/

int potentiometer = A0; //From the main potentiometer

int PWM = 3;

void setup() {

pinMode(potentiometer, INPUT);

pinMode(PWM, OUTPUT);

TCCR2B = TCCR2B & B11111000 | B00000001; // pin 3 and 11 PWM frequency of 31372.55 Hz

}

void loop() {

float voltage = analogRead(potentiometer);

int VALUE = map(voltage,0,1024,0,254);

analogWrite(PWM,VALUE);

}