chandresha1

Member level 2

- Joined

- Dec 4, 2010

- Messages

- 43

- Helped

- 3

- Reputation

- 6

- Reaction score

- 3

- Trophy points

- 1,288

- Location

- Bremen, Germany

- Activity points

- 1,673

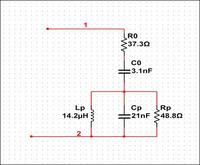

I am designing a passive analog filter for Digital to analog conversion. But i am stuck at one point. My load is not purely resistive. Actually i have to drive a piezo with my circuit. Piezo is an inductive and capacitive load. I don't have any idea about how to design filter for such kind of load. Could anyone tell me the possible method or some kind of tutorial?