campus189

Member level 5

- Joined

- May 7, 2011

- Messages

- 84

- Helped

- 0

- Reputation

- 0

- Reaction score

- 0

- Trophy points

- 1,286

- Location

- Tennessee,USA

- Activity points

- 1,940

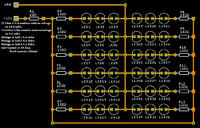

Want to power 24-led's for an emergency lighting project for when the power goes out.

Will be running off a 12 Volt deep cell marine battery that is charged by solar panels.

Led Specs- 3.2-3.4v 20mA each X 24 =480mA total

I am currently using these to go from 12 Volt to 5V.

The reason i'm using them is because I have alot of these & can get more cheap.

**broken link removed**

**broken link removed**

**broken link removed**

**broken link removed**

My output voltage on the adapter I have.....

Pin 1 ----Ground

Pin 2 ----2.1 Volts

Pin 3 ----2.8 Volts

Pin 4 ----5.2 Volts

Heres my question to you..

There are so many chips to choose from, i don't know where to start..

From what I can gather, My best options would be these chips listed below.

All these are TO-220 style

LM2678S-3.3 Max Voltage In- 12V,---5A

LM1117-3.3 Max Voltage In- 15V ---800mA

LM1086-3.3 MAx Voltage In- 5V,----1.5A

LM3940 MAx Voltage In- 5.5V---1.0A

Anyone got an idea which one to go with ?

If I can keep from using lots of resistors & other components, that would be great.

It looks like if I used the LM2678S-3.3 I would have a heatsink with alot of wasted power.

But, I wouldn't have to use the adapter above to go from 12v-3.3

It looks like the LM1117 or LM3940 would be best for this.

With the LM3940, it calls for a minimum output capacitance required to maintain stability. Which is 33 μF

Any recommendations on capacitors ? or should I go with the minimum?

According to datasheet, value may be increased without limit.

Larger values of output capacitance will give improved transient response.

ESR LIMITS:

The ESR of the output capacitor will cause loop instability if it

is too high or too low. The acceptable range of ESR plotted

versus load current is shown in the graph below. It is essential

that the output capacitor meet these requirements, or

oscillations can result.

Or would I be better off modifying the 12v adapters I have?

I have been working on this for a while now, modifying the 12 volt adapter and KJ6EAD has been helping me here.

I'm trying to K.I.S.S. (Keep It Simple Stupid) , lol

Any help would be appreciated..

Thank You

Will be running off a 12 Volt deep cell marine battery that is charged by solar panels.

Led Specs- 3.2-3.4v 20mA each X 24 =480mA total

I am currently using these to go from 12 Volt to 5V.

The reason i'm using them is because I have alot of these & can get more cheap.

**broken link removed**

**broken link removed**

**broken link removed**

**broken link removed**

My output voltage on the adapter I have.....

Pin 1 ----Ground

Pin 2 ----2.1 Volts

Pin 3 ----2.8 Volts

Pin 4 ----5.2 Volts

Heres my question to you..

There are so many chips to choose from, i don't know where to start..

From what I can gather, My best options would be these chips listed below.

All these are TO-220 style

LM2678S-3.3 Max Voltage In- 12V,---5A

LM1117-3.3 Max Voltage In- 15V ---800mA

LM1086-3.3 MAx Voltage In- 5V,----1.5A

LM3940 MAx Voltage In- 5.5V---1.0A

Anyone got an idea which one to go with ?

If I can keep from using lots of resistors & other components, that would be great.

It looks like if I used the LM2678S-3.3 I would have a heatsink with alot of wasted power.

But, I wouldn't have to use the adapter above to go from 12v-3.3

It looks like the LM1117 or LM3940 would be best for this.

With the LM3940, it calls for a minimum output capacitance required to maintain stability. Which is 33 μF

Any recommendations on capacitors ? or should I go with the minimum?

According to datasheet, value may be increased without limit.

Larger values of output capacitance will give improved transient response.

ESR LIMITS:

The ESR of the output capacitor will cause loop instability if it

is too high or too low. The acceptable range of ESR plotted

versus load current is shown in the graph below. It is essential

that the output capacitor meet these requirements, or

oscillations can result.

Or would I be better off modifying the 12v adapters I have?

I have been working on this for a while now, modifying the 12 volt adapter and KJ6EAD has been helping me here.

I'm trying to K.I.S.S. (Keep It Simple Stupid) , lol

Any help would be appreciated..

Thank You

Last edited: