paulked

Newbie level 3

Hi there.

I would like to solve a problem electronically rather than using relays (as I am doing at present).

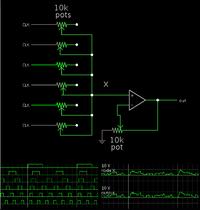

I have to control the speed of a pump (via 0-10V signal) depending on the demand from various sources. I have 6 sources and some require more pump output than others. If more than one source is demanding then those demands are added. The circuit I'm using at the moment is this:

X1-1 - X1-6 Demand inputs

X1-8 = 10V

X1-9 = Output

X1-10 = 0V

This works ok for fixed demands but every time any of the demands change I have to change the value of the resistors.

Any ideas how I should approach this electronically?

Best regards

Paul Ked

I would like to solve a problem electronically rather than using relays (as I am doing at present).

I have to control the speed of a pump (via 0-10V signal) depending on the demand from various sources. I have 6 sources and some require more pump output than others. If more than one source is demanding then those demands are added. The circuit I'm using at the moment is this:

X1-1 - X1-6 Demand inputs

X1-8 = 10V

X1-9 = Output

X1-10 = 0V

This works ok for fixed demands but every time any of the demands change I have to change the value of the resistors.

Any ideas how I should approach this electronically?

Best regards

Paul Ked