viperpaki007

Full Member level 5

Hi,

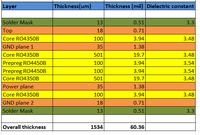

I am making an RF PCB (max frequency 8GHz). One manufacturer suggested the following layer stack for me (see attached figure). They use Rogers material as Rogers have good RF performance. My question: Is it necessary to use Roger material between central layers?. Central layers are used for Gnd and power plane and there are no RF signals routed on these layers so i am thinking that may be Roger material is not required between Central layers and only a FR4 material can work as well. Any comments?

I am making an RF PCB (max frequency 8GHz). One manufacturer suggested the following layer stack for me (see attached figure). They use Rogers material as Rogers have good RF performance. My question: Is it necessary to use Roger material between central layers?. Central layers are used for Gnd and power plane and there are no RF signals routed on these layers so i am thinking that may be Roger material is not required between Central layers and only a FR4 material can work as well. Any comments?