eepty

Full Member level 2

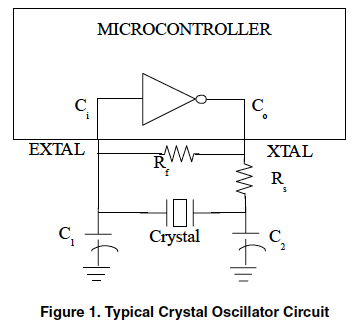

I have contacted the support engineer of the MCU, he confirmed the load capacitor value I used is correct (I use 18pF). And it is a mistake on their datasheet saying that no load capacitor is needed.

However, when I tried to decrease the load capacitor value to 12pF, I found the problem gone.

Another observation is that the board has a LCD, when I remove the LCD on few of the boards, the problem also gone. But this does not work on all of my boards.

In fact we have made over 200pcs of this board before and I did not see this problem. This problem occurs only recently.

Therefore I suspect that something is not compliant to the datasheet, the MCU or the crystal. Or my PCBA has a relatively large stray capacitance (so I need to use a lower value load capacitor and removing the LCD will decrease the stray capacitance a bit)? I do not know how to measure the stray capcitance on my PCB...

However, when I tried to decrease the load capacitor value to 12pF, I found the problem gone.

Another observation is that the board has a LCD, when I remove the LCD on few of the boards, the problem also gone. But this does not work on all of my boards.

In fact we have made over 200pcs of this board before and I did not see this problem. This problem occurs only recently.

Therefore I suspect that something is not compliant to the datasheet, the MCU or the crystal. Or my PCBA has a relatively large stray capacitance (so I need to use a lower value load capacitor and removing the LCD will decrease the stray capacitance a bit)? I do not know how to measure the stray capcitance on my PCB...