isurunalaka

Member level 5

Hi,

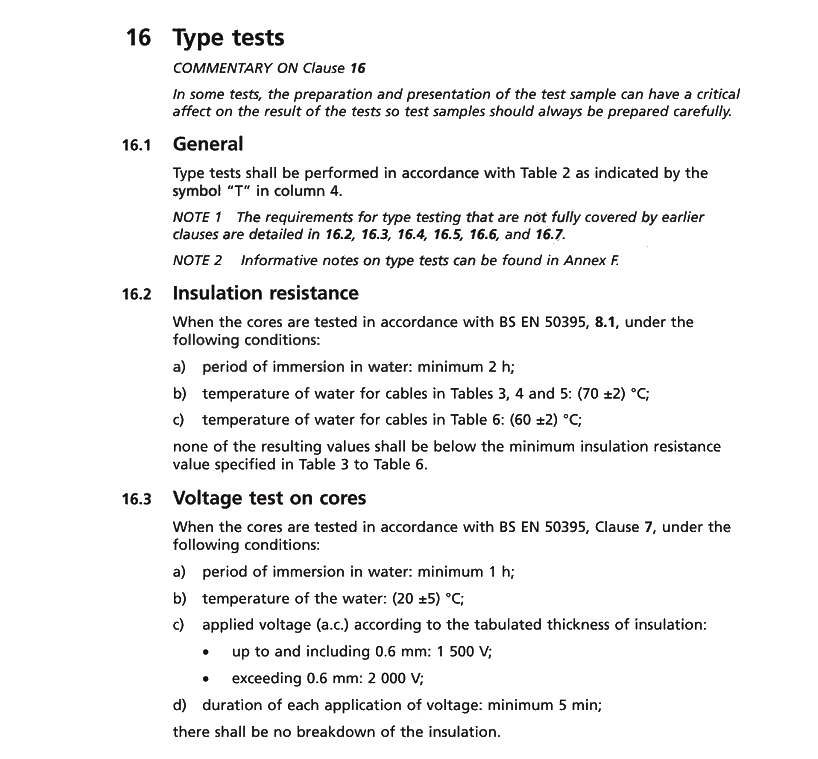

when low voltage cable manufacturing like 300v/500v, voltage test to be done for a 20m completed cable sample. To do this, 20m cable need to be immersed in water bath.

Can you please give me a reference for this complete test?

Thanks

- - - Updated - - -

anyone know about this?

when low voltage cable manufacturing like 300v/500v, voltage test to be done for a 20m completed cable sample. To do this, 20m cable need to be immersed in water bath.

Can you please give me a reference for this complete test?

Thanks

- - - Updated - - -

anyone know about this?