nigelmercier

Member level 2

- Joined

- Nov 3, 2009

- Messages

- 47

- Helped

- 0

- Reputation

- 0

- Reaction score

- 0

- Trophy points

- 1,286

- Location

- United Kingdom

- Activity points

- 1,622

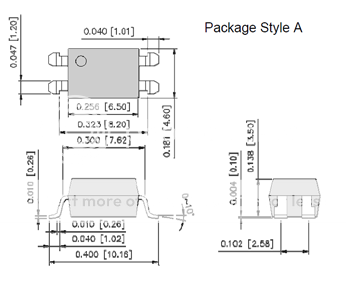

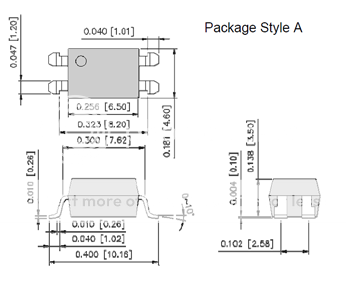

I have bought several OPTEK OPIA412ATU optocouplers, from the OPIA400 range. The datasheet doesn't give much in the way of soldering footprints, just that this type is "Package Style A", which may be an internal OPTEK name.

The dimensions are given thus:

Where can I find the soldering footprint?

The dimensions are given thus:

Where can I find the soldering footprint?