GH Crash

Member level 1

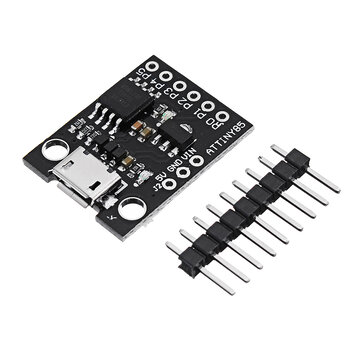

I have an idea floating around in my head but everything depends upon finding a micro size timer chip. The timer just has to turn on/off a MOSFET. By micro, I mean a chip smaller than a postage stamp.

Does anyone know of a micro size low voltage IC timer? All I need is the part number of such a timer, or where to I might find out more information about micro timers.

Thanks for any help you can give.

George

Does anyone know of a micro size low voltage IC timer? All I need is the part number of such a timer, or where to I might find out more information about micro timers.

Thanks for any help you can give.

George