- Joined

- Jan 22, 2008

- Messages

- 52,485

- Helped

- 14,756

- Reputation

- 29,794

- Reaction score

- 14,121

- Trophy points

- 1,393

- Location

- Bochum, Germany

- Activity points

- 298,363

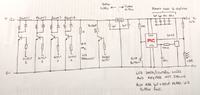

And to face the facts, it's unlikely to achieve regular EMI strength with the circuit. Some things, e.g. switching power loads with a relay near the circuit simply must be omitted.When using open wire construction there will never be a ground plane.