wolf12

Advanced Member level 4

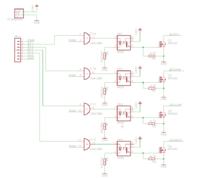

I'm trying to test following unipolar 2 phase stepper motor,

http://www.nidec-servo.com/en/digital/pdf/KH42K.pdf

I made a stepper motor driver with IRF640 mosfets and opto couplers for use with arduino,

I think of two possible causes,

1. I miswired the end points of the stepper motor

2. I was not using PWM or Resistors to limit the current to the motor and it was directly connected to 24V though mosfets,

which one is the cause?

If 'not using PWM' is the cause, can you tell me which duty and frequency should I use? And please suggest any additional protection for the motor.

Thank you.

http://www.nidec-servo.com/en/digital/pdf/KH42K.pdf

I made a stepper motor driver with IRF640 mosfets and opto couplers for use with arduino,

I think of two possible causes,

1. I miswired the end points of the stepper motor

2. I was not using PWM or Resistors to limit the current to the motor and it was directly connected to 24V though mosfets,

which one is the cause?

If 'not using PWM' is the cause, can you tell me which duty and frequency should I use? And please suggest any additional protection for the motor.

Thank you.