nima_1981

Member level 3

- Joined

- Apr 22, 2010

- Messages

- 61

- Helped

- 0

- Reputation

- 0

- Reaction score

- 0

- Trophy points

- 1,286

- Location

- Ocean Mind

- Activity points

- 1,877

Hi ,

How i can Design a Dc clamp base on hall effect .

I want To measure dc current 0 to 2000 Ampere with .5 Ampere resolution .

i can not break wire because i went to use clamp hall effect

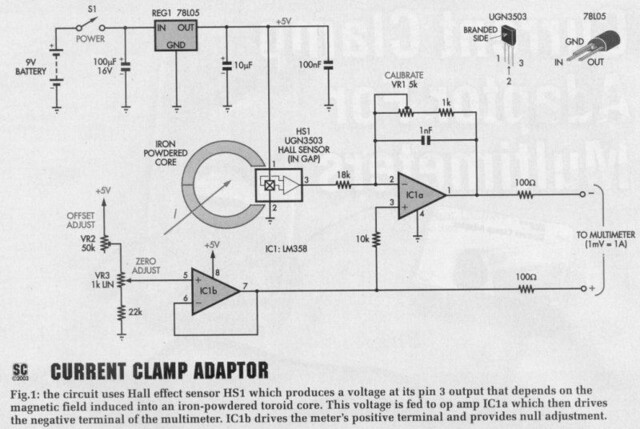

I Found this article, But i can not change this for 2000 Ampere

another , in this article does not have any specification for Iron Powerd Core ?

tahnk yiy

How i can Design a Dc clamp base on hall effect .

I want To measure dc current 0 to 2000 Ampere with .5 Ampere resolution .

i can not break wire because i went to use clamp hall effect

I Found this article, But i can not change this for 2000 Ampere

another , in this article does not have any specification for Iron Powerd Core ?

tahnk yiy

Last edited: